Aircraft Borescope Applications

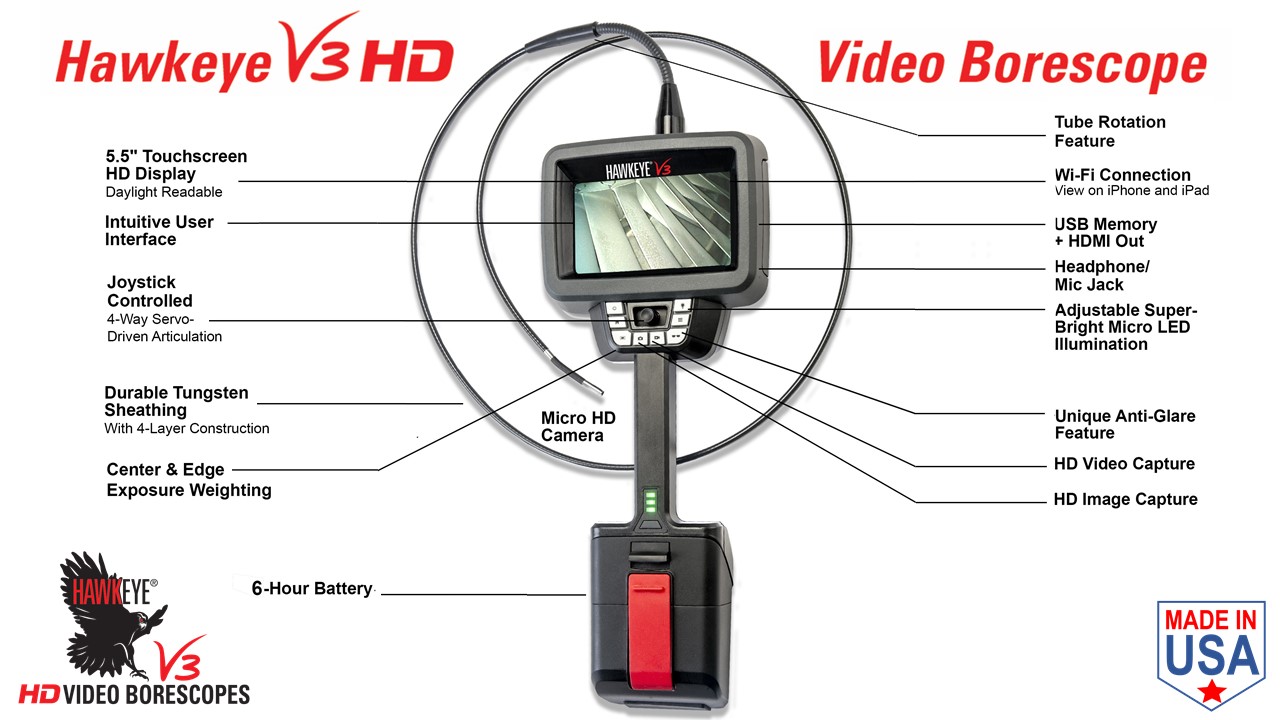

Hawkeye® borescopes allow aircraft maintenance technicians to perform inspections in the engine and airframe where it is impossible to see without tearing down the engine. Many of todays aircraft engines are “on-condition” which means they need to be inspected by a borescope at a certain interval of time to determine if the engine needs maintenance or can continue to fly. The quality of videoscopes is one borescope application that cannot by overlooked, like the new Hawkeye® V3 HD Videoscope, provide users with crystal clear, bright HD images and videos allowing them to easily identify the condition of an aircraft engine

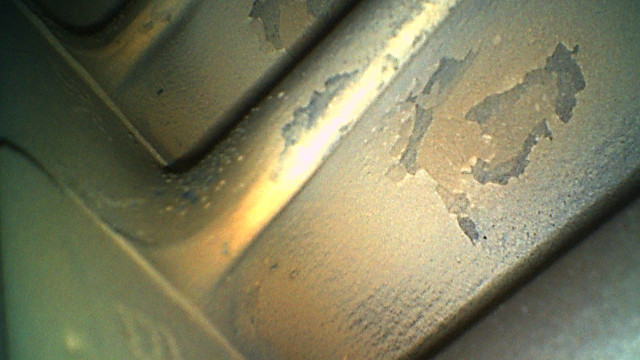

Turbine blades in a P&W PT6A-34 aircraft engine inspected with a Hawkeye® V3 HD Borescope.

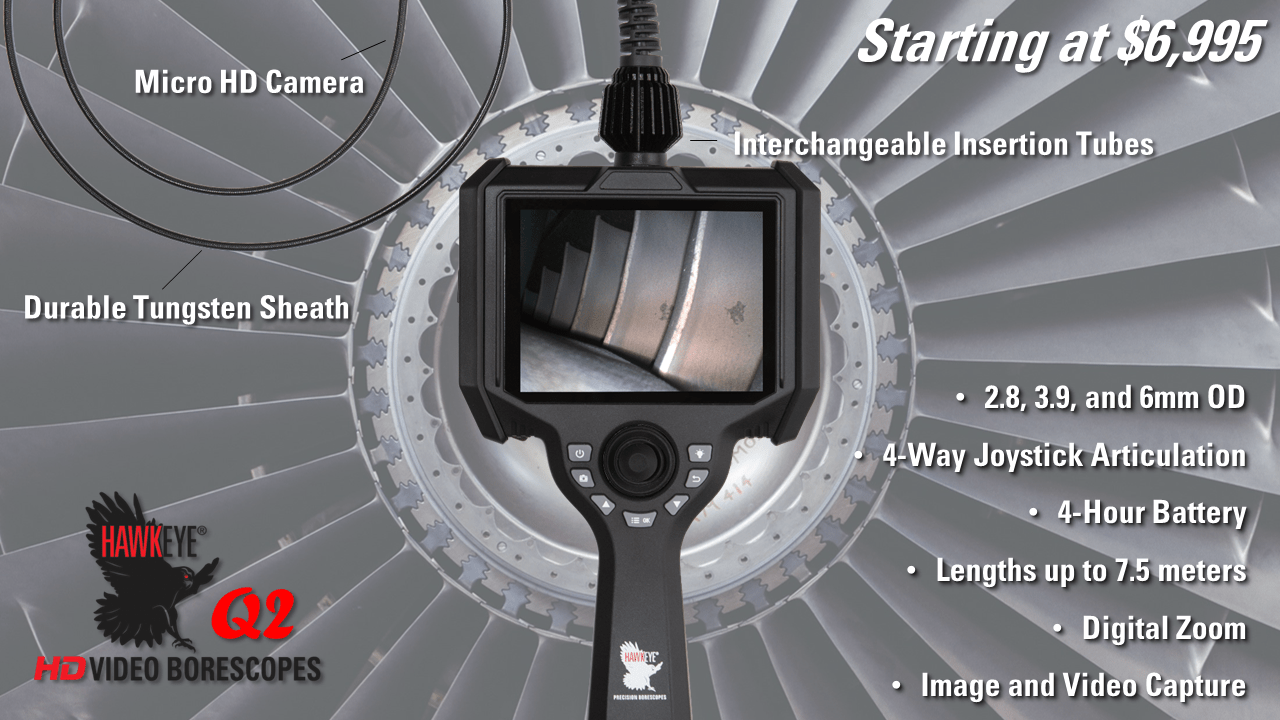

Allison 250 aircraft engine Inspection with a Hawkeye® Q2 HD Videoscope.

Fuel nozzle in a P&W PT6A-34 aircraft engine inspected with a Hawkeye® V3 HD Borescope

Tom Pentecost , VP of Maintenance and Flightline Group Inc. in Tallahassee, FL, and mechanic Stephanie Nita, use the borescope applications provided by the Hawkeye® V3 HD Videoscope with WiFi capability to simultaneously view the image on an iPad while inspecting a PT6A-34 engine.

If you have questions about other aircraft borescope applications, please give us a call at 800-536-0790; we look forward to speaking with you.